This is my own private collection of ramblings.. make of it what you will.. A happy remark would be appreciated and if complaining ..remember how much you paid ;)

Saturday, 30 April 2011

Thursday, 28 April 2011

Tuesday, 26 April 2011

Sunday, 24 April 2011

Dead Possum!

and sometimes you model stuff that just makes you go.. WTF???

(lol, this is actually a mock up of a model in tsplines i did for someone i know.. jsut for kicks, but it supposed to be a dead opossum.. New Zealanders....)

(lol, this is actually a mock up of a model in tsplines i did for someone i know.. jsut for kicks, but it supposed to be a dead opossum.. New Zealanders....)

quadball doggy....

dont ask.. moddeling organic stuff is still new to me... this started out life as a quadball.. The remnants of which are left in the throat area ;)

(Undigested cat???)

Friday, 22 April 2011

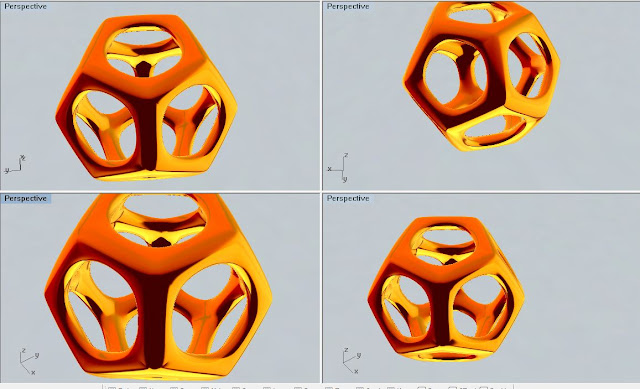

Triple Dodecahedron model..

I did a nurbs dodecahedron Frabjous model some time ago.. figured I would give Tsplines a go at it as well...

Here is the old original model I did.

Here is the old original model I did.

And this is the Tsplines version, starting at the polygonal dodecahedron

then the dual inner and outter triangle dodecahedron merge at their intersection points

and then finally the two together..

Wednesday, 20 April 2011

Sunday, 17 April 2011

Saturday, 16 April 2011

RhinoCam fully 2D puzzle bangle..

I am cutting this for someone else, its hardly an earth shattering design and i could have just done it as autoflip and rotary.. but.. I figured, what would be the most difficult way for me to do this..

Figure out the curves.. and cut the entire job as a 2d profiling and pocketing operation..

2 things i learned..

1: 2d work is trickier than it looks

2: In 2d this job will take 47mins @ 400mm/min.. in autoflip+rotary i was looking at 7 hours...

(it actually took 22 minutes to cut at +-900mm/min average velocity)

Figure out the curves.. and cut the entire job as a 2d profiling and pocketing operation..

2 things i learned..

1: 2d work is trickier than it looks

2: In 2d this job will take 47mins @ 400mm/min.. in autoflip+rotary i was looking at 7 hours...

(it actually took 22 minutes to cut at +-900mm/min average velocity)

Minitech / 123WaxRing Setup and Usage

I have long been enamoured by the fixture from Lex at DeskProto and after some discussion he happily provided me with a unit for testing. I have copied this post from our old forum where more in depth information is available.

I locked the fixture into my Sherline rotary and the time arrived to dial this sucker in!

The fixture relies on a perfect A and Z and X setup, Y and Z should both already be setup before you even set this fixture up since you will be locking into your rotary unit and would have this dialled in.

Lets get to it!

1: Finding perfect A... easy! roll the whole unit in A against a table square on your mill table, set your jog to 10% and slowly roll until no light is visible between the square blade and the fixtures top surface.

2: Click in the A DRO in Mach and type in 90 (or 270 depending on which side you setup the fixture table) then run the command G0A0. Simple - A is now perfectly flat to the spindle and A is now set :)

.JPG)

3: Time to setup X.. this too is pretty easily done, but make sure you are 100% carefull in this step, the 123waxringWizard software relies on X heavily, even a minor misalignment here will be amplified in your final model.. measure twice, cut once. To setup X drive the back of a 3.17 (1/8th) cutter up to the very edge of the fixture like below, CAREFULLY, set your jog speed right down when you get closer. when you are touching the fixture zero out X and drive directly upwards in Z away from the fixture, now time to correct our tooltip width, run the command G0X-1.585 then rezero X. Thats it for X.

.JPG)

4: these images are merely the way that I verified my Y before cutting, I am including them because all thing swith movable parts are subject to tolerances so screwing the fixture into its Sherline adapter may introduce errors, and even tho they are minor in most case its good to know how to look for them. Basically i drove my cutter to the very edge of each pin in Y and check the Mach DRO for position in Y on either pin, these should be virtually the same number only different in positive/negative assignment. Y verified!

.JPG)

.JPG)

.JPG)

.JPG)

5: Time to cut.. The software would have told you what thickness disk to use, lock it in the fixture with the chosen cutter in place and probed.

The first path will complete with half the disk cut away to reveal one side of the ring.

.JPG)

.JPG)

Turn the disk over and lock it back in. Cut the second path, you should be left with a well aligned flip cut wax, ready for the final rotary pass.

.JPG)

Lock it onto the rotary pins and lets finish this up!

.JPG)

.JPG)

And we are done!

Thank you for taking some time to read through this pictorial :)

.JPG)

.JPG)

Regards

Chris Botha

I locked the fixture into my Sherline rotary and the time arrived to dial this sucker in!

The fixture relies on a perfect A and Z and X setup, Y and Z should both already be setup before you even set this fixture up since you will be locking into your rotary unit and would have this dialled in.

Lets get to it!

1: Finding perfect A... easy! roll the whole unit in A against a table square on your mill table, set your jog to 10% and slowly roll until no light is visible between the square blade and the fixtures top surface.

2: Click in the A DRO in Mach and type in 90 (or 270 depending on which side you setup the fixture table) then run the command G0A0. Simple - A is now perfectly flat to the spindle and A is now set :)

.JPG)

3: Time to setup X.. this too is pretty easily done, but make sure you are 100% carefull in this step, the 123waxringWizard software relies on X heavily, even a minor misalignment here will be amplified in your final model.. measure twice, cut once. To setup X drive the back of a 3.17 (1/8th) cutter up to the very edge of the fixture like below, CAREFULLY, set your jog speed right down when you get closer. when you are touching the fixture zero out X and drive directly upwards in Z away from the fixture, now time to correct our tooltip width, run the command G0X-1.585 then rezero X. Thats it for X.

.JPG)

4: these images are merely the way that I verified my Y before cutting, I am including them because all thing swith movable parts are subject to tolerances so screwing the fixture into its Sherline adapter may introduce errors, and even tho they are minor in most case its good to know how to look for them. Basically i drove my cutter to the very edge of each pin in Y and check the Mach DRO for position in Y on either pin, these should be virtually the same number only different in positive/negative assignment. Y verified!

.JPG)

.JPG)

.JPG)

.JPG)

5: Time to cut.. The software would have told you what thickness disk to use, lock it in the fixture with the chosen cutter in place and probed.

The first path will complete with half the disk cut away to reveal one side of the ring.

.JPG)

.JPG)

Turn the disk over and lock it back in. Cut the second path, you should be left with a well aligned flip cut wax, ready for the final rotary pass.

.JPG)

Lock it onto the rotary pins and lets finish this up!

.JPG)

.JPG)

And we are done!

Thank you for taking some time to read through this pictorial :)

.JPG)

.JPG)

Regards

Chris Botha

RingSize Cutter Setup on Minitech

Hi all, another copy of an older post being imported to our new shiny forum :)

If like me, you find yourself to be loosing the manual dexterity required to get in small areas without destroying a wax, I will bet you are wishing you had a tool for separating your core from your ring without all the PITA...

Well I use Brants arbor for my cutting and it occurred to me after seeing Leo's post on his cutter that it could not be so hard to do! This pictorial covers that bit of journey ;)

1: Find some nice extruded acrylic and a imperial bolt.. turn the acrylic blank in your lathe and glue the cut off bolt into it.. simple enough? No lock it into your 4 jaw chuck and simply mill a copy of Brants Arbor into the front of it! Thank you Colin for your help here!

2: screw that sucker down to a handy spot on your mill table, make sure it snot a place that your spindle assembly will crash into anything else.

3: drive to its dead centre (little spot in my case left from turning it) and svae X and Y and Z as a fixture offset in MACH.

4: Usage.. cut a regulr flip, followed by a regular rotary pass as per usual.

5: Move the ring over to the new acrylic fixture on the table, nice snug fit! Run some code to cut the fingersize, in my case i use the following recipe but you can use the circle cutting wizards in mach too or simply code a cutoff path in your favourite pathing application.

[QUOTE](Radius Fingersize)-(Radius Cutter) and replace the three sections marked in red with that result. the section marked in green is where you would set your depth.

My offset in mach is setup to X and Y being at the center of the hub and Z0 being at the top of the fixture, which is 6mm deep, so basically anything over z-3 will be cutting below the middle of the model. In this case z-5 which is 2mm below the center of the model, easily cutting through the supports.

G00 Z10.0000

X0.0000 Y6.8000

G01 Z-5.000 F150.0

G17

G03 Y-6.8000 I0.0000 J0.0000

Y6.8000 I0.0000 J0.0000

G00 Z50.0000

G00 Y0.0000

M05

M30

[/QUOTE]

6: and she is done!

Thanks for reading the full pictorial and I hope it helps you in some way,

Regards

Chris Botha.

If like me, you find yourself to be loosing the manual dexterity required to get in small areas without destroying a wax, I will bet you are wishing you had a tool for separating your core from your ring without all the PITA...

Well I use Brants arbor for my cutting and it occurred to me after seeing Leo's post on his cutter that it could not be so hard to do! This pictorial covers that bit of journey ;)

1: Find some nice extruded acrylic and a imperial bolt.. turn the acrylic blank in your lathe and glue the cut off bolt into it.. simple enough? No lock it into your 4 jaw chuck and simply mill a copy of Brants Arbor into the front of it! Thank you Colin for your help here!

2: screw that sucker down to a handy spot on your mill table, make sure it snot a place that your spindle assembly will crash into anything else.

3: drive to its dead centre (little spot in my case left from turning it) and svae X and Y and Z as a fixture offset in MACH.

4: Usage.. cut a regulr flip, followed by a regular rotary pass as per usual.

5: Move the ring over to the new acrylic fixture on the table, nice snug fit! Run some code to cut the fingersize, in my case i use the following recipe but you can use the circle cutting wizards in mach too or simply code a cutoff path in your favourite pathing application.

[QUOTE](Radius Fingersize)-(Radius Cutter) and replace the three sections marked in red with that result. the section marked in green is where you would set your depth.

My offset in mach is setup to X and Y being at the center of the hub and Z0 being at the top of the fixture, which is 6mm deep, so basically anything over z-3 will be cutting below the middle of the model. In this case z-5 which is 2mm below the center of the model, easily cutting through the supports.

G00 Z10.0000

X0.0000 Y6.8000

G01 Z-5.000 F150.0

G17

G03 Y-6.8000 I0.0000 J0.0000

Y6.8000 I0.0000 J0.0000

G00 Z50.0000

G00 Y0.0000

M05

M30

[/QUOTE]

6: and she is done!

Thanks for reading the full pictorial and I hope it helps you in some way,

Regards

Chris Botha.

Mdx15+FourthAxis and 123Waxring setup.

Hi All,

Having set up and used the 123WaxRing fixture on my Minitech Minimill I was very taken with it, and noticed one important thing about it, it is SMALL!!

So small in fact that I was pretty sure I could get it to fit inside my MDX-15. This is no small feat by the way for those of you unfamiliar with an MDX-15.. its Z space is extremely limited.

Anyhow, in case anyone ever feels the need to hook up a good fixture to a neat little hobby mill I hope the following pictorial will help you :)

What will you need?

1: 123Waxring fixture.. and obviously Deskproto.

2: an MDX15 mill

3: A Fourth Axis after-market rotary unit.

Lets get to it!

1: The first problem I had to overcome was how to fit this onto my rotary unit.. not an easy one to overcome as the rotary unit cannot support much weight as it is so a tight slimline method was required, I tested a few ways but gave up on them and then settled on the next method. I took one of my supplied Spigot Boss's and hooked it into my lather, I cut a ledge the same size as the ledge on my 123waxring fixture, to ensure a nice concentric fit..

2: I eventually found the right size bolt to fit into the back of the 123waxring fixture and bored and glued it into my spigot boss.

Which resulted in a nice clean slim setup!

3: time to see if it would fit .. it did! wooooooooohooooooooooo

4: Dialling it in is slightly more complicated than the process found here because of the poorer controller system available to these units, but the principals are the same. A slightly more manual approach is required, but if you own an MDX15 you are already accustomed to doing everything slightly harder.

Time to load a path and test it!

5: Flips cut good!

6: let that rotary run!

and the finished result was damn good!

All up I would have to say that I am glad I own a Minitech now and I am not reliant on my MDX, but if I was then I have to say that this route of MDX15+FA+123WaxRing would be the only way to use it. The features of the 123WaxRing system, not requiring a 180 flip and using one X all the way through make usage of the complete system far simpler than any other method. If you setup your X, Y and Z datums once and then didnt turn off the mdx or close the controller application you could hypothetically cut as many rings as you liked after each other without any further setups.

If you are doing this or want to do this and are unsure please feel free to email me on the board for more detailed information.

Kind regards

Chris Botha

Having set up and used the 123WaxRing fixture on my Minitech Minimill I was very taken with it, and noticed one important thing about it, it is SMALL!!

So small in fact that I was pretty sure I could get it to fit inside my MDX-15. This is no small feat by the way for those of you unfamiliar with an MDX-15.. its Z space is extremely limited.

Anyhow, in case anyone ever feels the need to hook up a good fixture to a neat little hobby mill I hope the following pictorial will help you :)

What will you need?

1: 123Waxring fixture.. and obviously Deskproto.

2: an MDX15 mill

3: A Fourth Axis after-market rotary unit.

Lets get to it!

1: The first problem I had to overcome was how to fit this onto my rotary unit.. not an easy one to overcome as the rotary unit cannot support much weight as it is so a tight slimline method was required, I tested a few ways but gave up on them and then settled on the next method. I took one of my supplied Spigot Boss's and hooked it into my lather, I cut a ledge the same size as the ledge on my 123waxring fixture, to ensure a nice concentric fit..

2: I eventually found the right size bolt to fit into the back of the 123waxring fixture and bored and glued it into my spigot boss.

Which resulted in a nice clean slim setup!

3: time to see if it would fit .. it did! wooooooooohooooooooooo

4: Dialling it in is slightly more complicated than the process found here because of the poorer controller system available to these units, but the principals are the same. A slightly more manual approach is required, but if you own an MDX15 you are already accustomed to doing everything slightly harder.

Time to load a path and test it!

5: Flips cut good!

6: let that rotary run!

and the finished result was damn good!

All up I would have to say that I am glad I own a Minitech now and I am not reliant on my MDX, but if I was then I have to say that this route of MDX15+FA+123WaxRing would be the only way to use it. The features of the 123WaxRing system, not requiring a 180 flip and using one X all the way through make usage of the complete system far simpler than any other method. If you setup your X, Y and Z datums once and then didnt turn off the mdx or close the controller application you could hypothetically cut as many rings as you liked after each other without any further setups.

If you are doing this or want to do this and are unsure please feel free to email me on the board for more detailed information.

Kind regards

Chris Botha

Subscribe to:

Comments (Atom)